How Rubber Innovation is Revolutionizing the Review Process in High-Stakes Industries

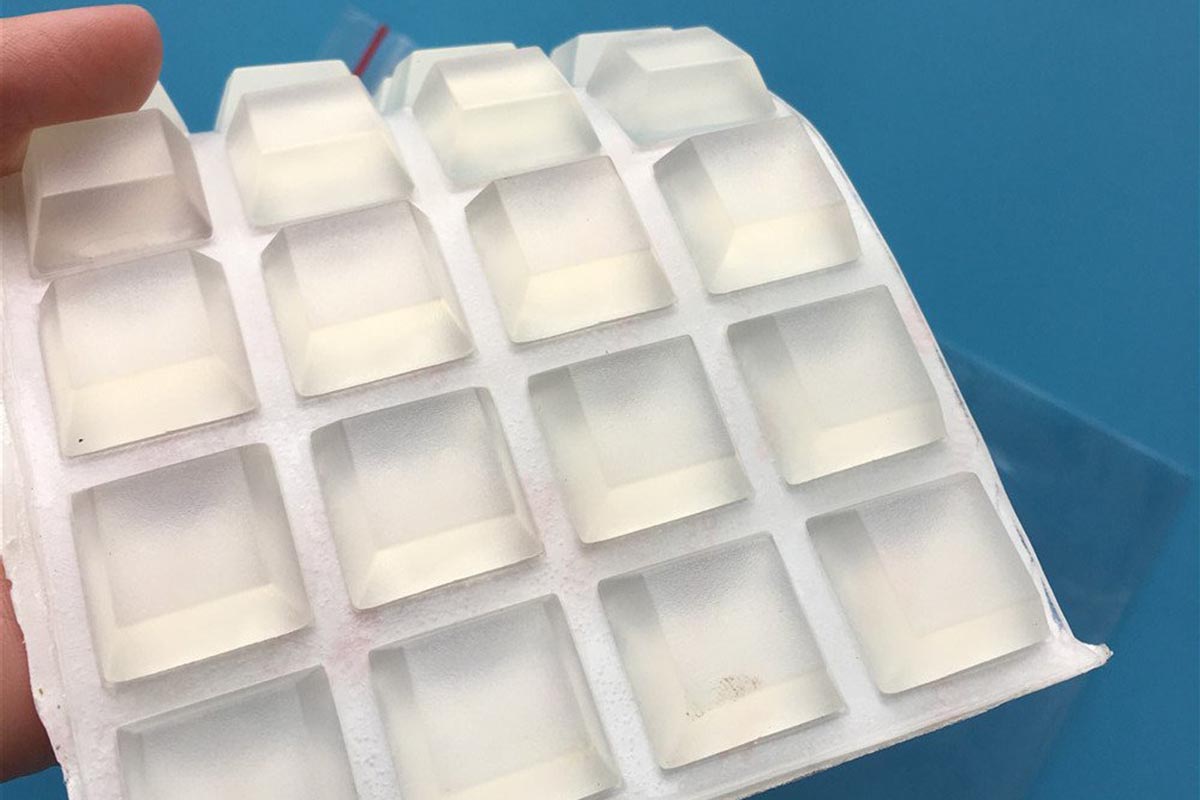

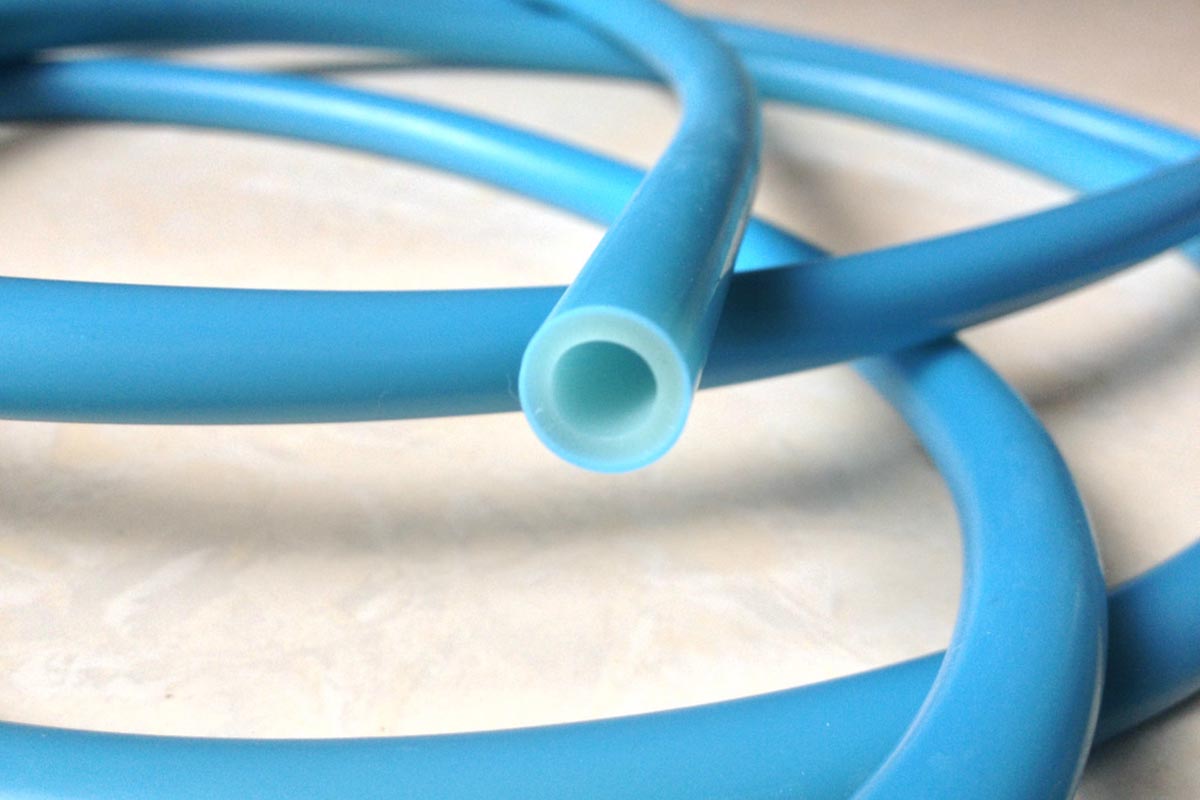

Revolutionize high-stakes industries with rubber innovation in review processes. Harness the power of thermoplastic elastomers (TPEs) to create durable, flexible components that withstand rigorous testing. Utilize interactive game powerpoint templates to engage stakeholders and streamline feedback collection. Implement advanced rubber compounds, like self-healing polymers, to reduce maintenance and extend product lifecycles. Partner with experienced rubber manufacturers to develop custom solutions tailored to your specific …