How Thermoplastic Elastomers are Revolutionizing Vaping Materials in the Industry

Leverage thermoplastic elastomers (TPEs) to enhance the durability and flexibility of vapotage centre-ville Montreal vaping components. Optimize product longevity by incorporating TPEs, which offer superior resistance to mechanical wear and environmental stressors. Innovate with custom formulations that improve the precision of vape designs, ensuring optimal performance. Compare TPEs with traditional materials to highlight improvements in flexibility, sustainability, and user safety. Explore advancements in TPE technology to drive further innovation within the industry, creating opportunities for bespoke, high-performing vaping devices.

Properties of Thermoplastic Elastomers Beneficial for Vaping

Flexibility and Durability

Thermoplastic elastomers (TPEs) are revolutionizing the vaping industry by offering unparalleled flexibility and durability, essential for the design and longevity of advanced vaping products. The inherent elasticity of TPEs allows for intricate design possibilities while maintaining a robust structure, crucial for applications that demand high-wear resistance and resilience. This flexibility enables manufacturers to develop customized solutions tailored to meet specific performance criteria, ensuring optimal user experience and satisfaction.

In terms of durability, TPEs offer superior resistance to environmental stressors such as temperature variations and chemical exposure, which are common in vaping devices. Their ability to withstand repeated mechanical stresses without compromising structural integrity significantly extends the lifespan of these products. Furthermore, TPEs’ innovative combination of rubber-like properties with thermoplastic processes enables efficient manufacturing and recycling, aligning with sustainability goals and reducing production costs.

By integrating TPEs into vaping products, industry professionals can leverage these materials’ unique properties to push technological boundaries, ensuring durability and flexibility without sacrificing design innovation.

Chemical and Heat Resistance

Thermoplastic elastomers (TPEs) are integral to the safety and functionality of vaping devices due to their exceptional chemical and heat resistance properties. In vaping applications, these materials face demanding conditions that require stability against high temperatures and contact with aggressive substances, such as e-liquids. TPEs exhibit outstanding resistance to various chemicals, including solvents and oils, which ensures they do not degrade when exposed to the complex compounds found in vaping environments.

Moreover, the thermal stability of TPEs is crucial as vaping devices regularly encounter elevated temperatures. TPEs maintain integrity at temperatures often exceeding typical stress limits, providing a robust barrier against thermal degradation. This characteristic not only enhances longevity but also prevents the release of potentially harmful substances, promoting a safer experience for users. Furthermore, innovative advancements in TPE formulations allow for the development of custom solutions that cater to specific vaping device requirements, providing manufacturers the flexibility to improve device performance and safety standards.

Overall, the ability of TPEs to withstand chemical and heat stress underpins their role as a reliable choice for vaping materials. As the industry progresses, leveraging these properties will continue to facilitate technological advancements and set new benchmarks in the design and functionality of vaping devices.

Innovative Uses of Thermoplastic Elastomers in Vaping Devices

Custom Design Solutions

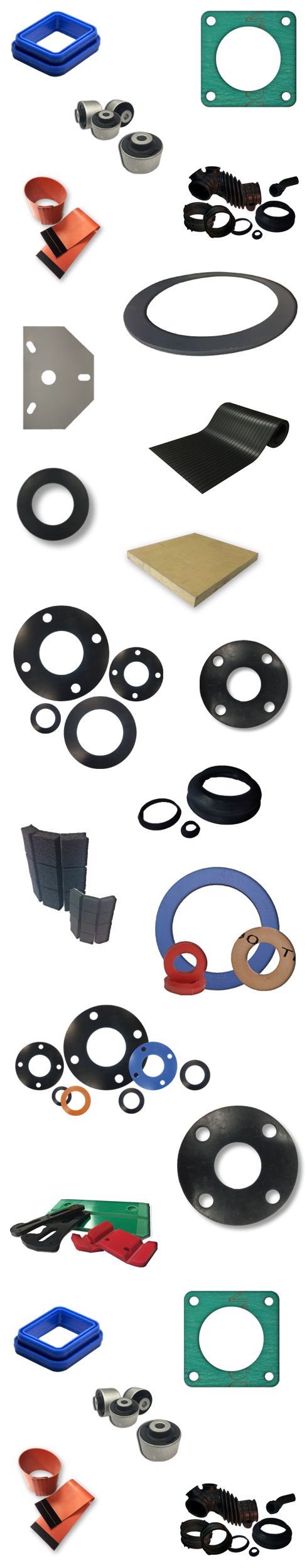

In the rapidly evolving vaping industry, thermoplastic elastomers (TPEs) are paving the way for innovative design solutions tailored to meet specific functional needs. Engineers are leveraging the unique properties of TPEs, such as elasticity, chemical resistance, and thermal stability, to create vaping products that not only enhance user experience but also elevate performance standards. By focusing on customized design options, manufacturers are able to integrate TPEs into ergonomic mouthpieces, flexible seals, and impact-resistant casings, optimizing each component for user comfort and durability. Through advanced simulation and prototyping techniques, these materials allow for precise modifications that enhance the overall functionality of vaping devices. Furthermore, TPEs’ versatility supports diverse textural and color variations, aligning with consumer expectations for personalized aesthetics without compromising on safety and efficiency. Highlighting the link between TPEs and customized rubber products offers additional insights into the engineering possibilities these materials present. As industry professionals delve deeper into TPEs’ capabilities, these elastomers are increasingly seen as essential components in the quest for market differentiation and sustainable innovation. Their application in the vaping sector exemplifies how custom solutions can address both regulatory requirements and dynamic market trends, ensuring the creation of sophisticated and reliable vaping devices.

Advancements in Vaping Technology

Recent advancements in vaping technology have been significantly driven by the innovative application of thermoplastic elastomers (TPEs), which present a versatile solution tailored to meet the specific demands of the industry. TPEs offer a unique combination of elasticity, durability, and thermal stability, making them ideally suited for the dynamic environment of vaping devices. Their ability to be customized enhances both performance and safety, vital factors in the design and manufacture of next-generation vaping products.

One of the key innovations facilitated by TPEs is the development of ergonomic and resilient components. The material’s flexibility allows for intricate designs and improved grip, catering to the evolving preferences of consumers seeking enhanced user experiences. Additionally, TPEs’ resistance to wear and environmental stressors ensures longevity in high-use applications, reducing the frequency of replacements and aligning with sustainable manufacturing practices.

The integration of TPEs into vaping technology has also enabled advancements in thermal management. Their impressive heat resistance helps in maintaining optimal device performance without compromising structural integrity. This attribute is particularly crucial as devices become more compact and powerful, requiring efficient heat dissipation. As the vaping sector continues to innovate, TPEs remain at the forefront, providing custom solutions that exceed traditional material limitations, paving the way for future advancements in this rapidly evolving industry.

Comparative Analysis: TPEs vs. Traditional Materials

Benefits Over Traditional Materials

Thermoplastic elastomers (TPEs) present a significant advancement over traditional materials, such as metals and more rigid polymers, particularly in the context of vaping materials. TPEs combine the elasticity of rubbers with the processability of plastics, making them a better alternative to silicone and other materials used in similar applications. This combination provides enhanced flexibility and durability, which are critical for vaping components that experience frequent handling and environmental exposure.

The adaptability of TPEs enables engineers to design custom solutions tailored to specific needs, providing a level of precision that traditional materials struggle to match. Their lightweight nature reduces overall product weight without compromising structural integrity, an essential factor in the design of portable devices. Moreover, TPEs exhibit superior resistance to chemicals, UV light, and temperature variations, ensuring longevity and consistent performance.

In terms of production efficiency, TPEs facilitate a more sustainable manufacturing process due to their reusability and ease of recycling. This not only reduces waste but also lowers production costs, making TPEs a cost-effective choice for the industry. The innovation inherent in TPEs aligns with technological advancements in vaping materials, pushing the boundaries of what is possible and setting new standards for quality and performance.

Challenges and Considerations

The implementation of thermoplastic elastomers (TPEs) in vaping products presents several challenges and important considerations. One primary concern is ensuring the material’s compatibility with e-liquids, as TPEs must resist degradation or unwanted chemical interactions that could compromise product safety and functionality. Engineers must also address potential off-gassing under varying temperature conditions, which necessitates rigorous testing to ensure air quality and user safety standards.

Another challenge lies in achieving the right balance of flexibility and durability. TPEs need to withstand repeated mechanical stresses without compromising structural integrity or performance. The selection of the right TPE grade is critical, as custom solutions may be required to tailor properties like hardness, elasticity, and thermal resistance to the specific demands of vaping devices.

Cost considerations also play a crucial role in material selection. While TPEs offer versatility and design flexibility, manufacturers must evaluate whether these benefits justify their investment compared to alternative materials. Addressing these challenges requires a detailed understanding of material science and a commitment to ongoing innovation in TPE applications.

Future Prospects and Job Opportunities in the TPE Vaping Sector

Emerging Trends and Innovations

The use of thermoplastic elastomers (TPEs) in vaping materials is poised for significant innovations. Industry professionals are exploring custom solutions that enhance both the safety and functionality of vaping products. These advanced TPE formulations emphasize improved thermal resistance and chemical stability, crucial for maintaining device integrity under varying conditions. Recent developments focus on bio-based and recyclable TPEs, aligning with global sustainability trends while offering superior resilience. Future trends suggest a shift towards multifunctional TPEs that incorporate antimicrobial properties, providing added health benefits. With ongoing research, TPEs are expected to foster more ergonomic and aesthetically appealing designs in the vaping industry.

Career Opportunities

The growing application of thermoplastic elastomers (TPEs) in vaping technology has opened exciting career opportunities for professionals specializing in material science, product design, and engineering. As the vaping industry continuously seeks innovative solutions to enhance performance and user experience, expertise in TPEs is increasingly in demand. Engineers with a deep understanding of polymer behavior are essential in developing custom TPE formulations tailored to optimize durability, flexibility, and thermal conductivity.

Product developers and design engineers can leverage their skills in creating advanced vaping components that meet stringent regulatory standards while providing superior tactile and aesthetic properties. Additionally, roles in quality assurance and regulatory affairs are pivotal, ensuring that new TPE-based products adhere to safety regulations and industry guidelines. Research scientists focusing on polymer advancements can explore the potential of bio-based and sustainable TPE options, aligning with the industry’s growing emphasis on eco-friendly solutions. Career paths in this dynamic field offer engineers and scientists a chance to contribute to cutting-edge innovations and the evolution of vaping materials.

Conclusion

Thermoplastic elastomers (TPEs) have significantly advanced the vaping industry by offering customizable solutions that enhance device performance and user safety. Their unique properties, such as flexibility, durability, and resistance to wear, make TPEs ideal for high-demand applications. As the industry continues to evolve, TPEs are at the forefront, driving innovation and supporting the development of safer, more efficient vaping devices. By leveraging TPEs’ versatility, engineers and manufacturers can design products that meet the dynamic needs of the market. This demands skilled professionals, highlighting exciting jobs as a rubber technologist.